What is a Hydro Pneumatic System?

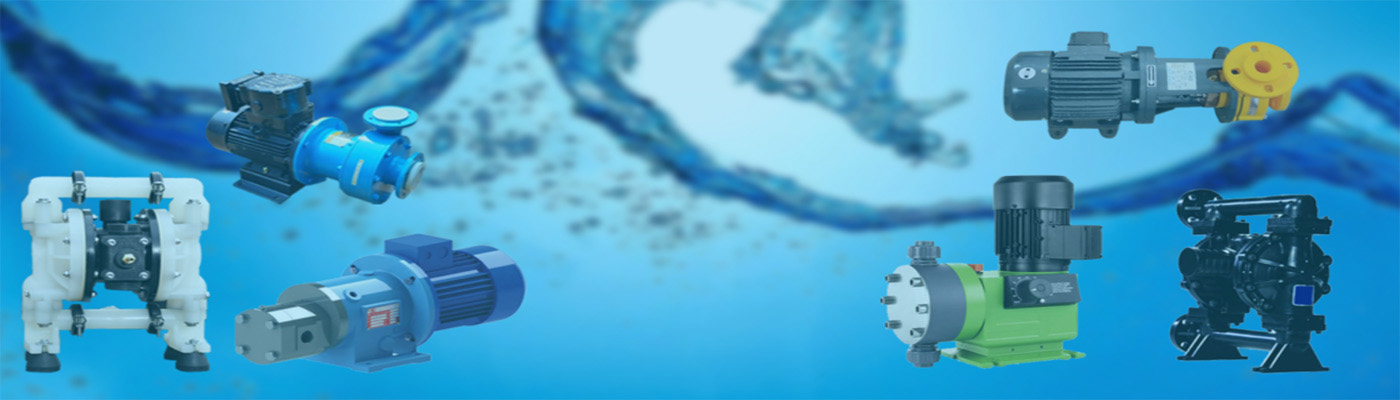

Pressurized air and water are combined in a hydro pneumatic tank. Due to the lack of a bladder in the system, the air will come into direct contact with the water. These systems primarily serve three purposes. They are

- Delivers water within a specific pressure range, reducing the need for a good pump to work continually.

- Prevents a pump from turning on each time the water distribution system experiences a small water demand.

- Minimizes pressure surges (water hammer).

In the household, agricultural, and industrial sectors, water pressure is a major problem. In addition to many other uses, hydro pneumatic pumps are utilized to increase pressure in residences and tall structures. These pumps are extremely energy efficient since they maintain a constant pressure level.

https://www.gdrpumps.com/wp-content/uploads/2022/09/Hydro-Pneumatic-Systems.jpg

464

570

enviro_gdr

https://www.gdrpumps.com/wp-content/uploads/2022/10/GDR-Logo.png

enviro_gdr2022-11-24 06:33:162022-11-24 09:57:21Hydro Pneumatic Pumps in Chennai

https://www.gdrpumps.com/wp-content/uploads/2022/09/Hydro-Pneumatic-Systems.jpg

464

570

enviro_gdr

https://www.gdrpumps.com/wp-content/uploads/2022/10/GDR-Logo.png

enviro_gdr2022-11-24 06:33:162022-11-24 09:57:21Hydro Pneumatic Pumps in Chennai