Why it is important to choose the right Dewatering methods?

Excessive water on a building site can endanger your project’s safety, increase expenses, and cause delays. Therefore, it is crucial to adopt the appropriate technique to control, manage, and remove water when getting ready to excavate the surface or carry out dry site construction operations. This becomes even more important as geology and hydrology will vary from location to location.

Main dewatering techniques

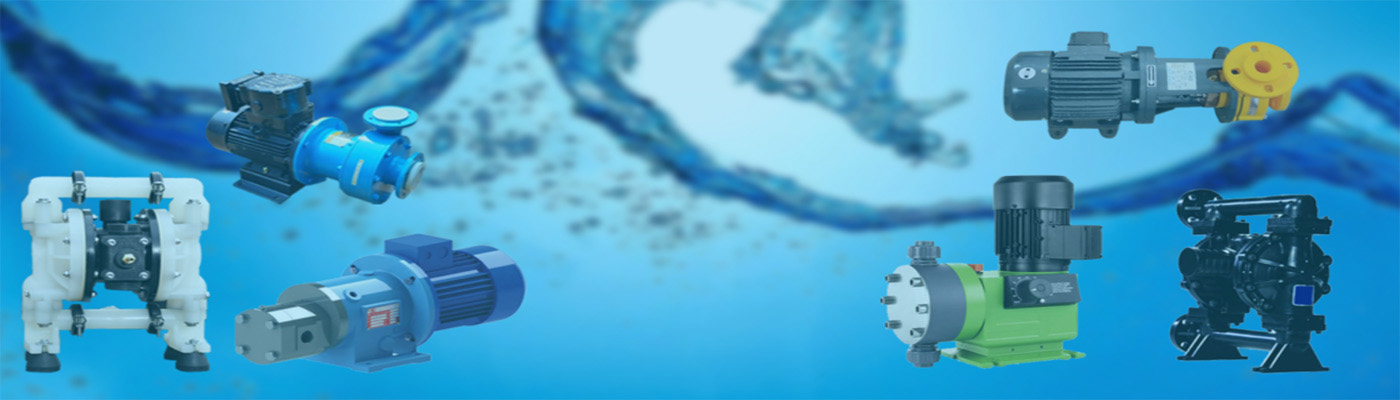

Construction dewatering methods refer to techniques such as well points, deep wells, bypasses, and flood control. Submersible pumps are positioned in drilled well shafts for WellPoint and deep wells, and in the dewatering area for bypass and flood control pumps. Let’s go over these standard methods.

Well Point

WellPoint involves drilling wells all around the excavation site and installing submersible pumps in the good shaft. The groundwater can be brought up by these pumps into the Well points and then released because they are connected to a header pipe.

Deep wells

In a Deep well, one or several individual wells are drilled, and submersible pumps are placed in each shaft. The Deep well technique is best suited for deep excavations where large water volumes need to be discharged.

Bypass dewatering

Dewatering pumps are used to move the sewage flow around the broken pipe segment when sewer systems need maintenance. The pumps are set up upstream of the pipe segment that needs maintenance. The bypass approach is frequently used in construction and irrigation operations.

Flood control

Flood control refers to all methods used to decrease or prevent harmful effects of flooding for example stormwater and heavy rainfall. Site managers must be ready for probable site flooding during building, tunneling, or mining operations by storing pumps that can transport large volumes of water against low head pressure close by.

Tunneling dewatering

Construction sites for tunnels can be complicated, and numerous factors must be taken into account. To stabilize the ground or avoid flooding the work area, sizable amounts of water from the building site must be removed.

https://www.gdrpumps.com/wp-content/uploads/2022/09/Hydro-Pneumatic-Systems.jpg

464

570

enviro_gdr

https://www.gdrpumps.com/wp-content/uploads/2022/10/GDR-Logo.png

enviro_gdr2022-11-24 06:33:162022-11-24 09:57:21Hydro Pneumatic Pumps in Chennai

https://www.gdrpumps.com/wp-content/uploads/2022/09/Hydro-Pneumatic-Systems.jpg

464

570

enviro_gdr

https://www.gdrpumps.com/wp-content/uploads/2022/10/GDR-Logo.png

enviro_gdr2022-11-24 06:33:162022-11-24 09:57:21Hydro Pneumatic Pumps in Chennai